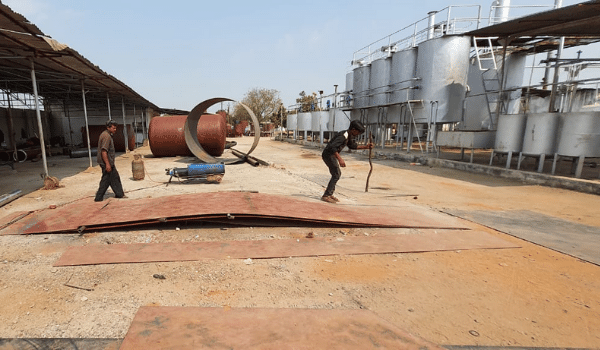

Bio Diesel Manufacturing Unit

Biodiesel Processing Plant/Biodiesel Manufacturing Plant

Biodiesel is a renewable alternative fuel created from vegetable oils, non edible oil and fats oil through a chemical process. the chemical process involves reaction of natural oils with an alcohol in the presence of a catalyst usually sodium hydroxide [naoh] or potassium hydroxide [koh] and then refining the mixture to create molecules which can be easily burned in a diesel engine.

Feed stock

Low grade feed stock

This includes used cooking oil, acid oil, low grade fatty acid, high ffa vegetable oil.

High grade feed stock

This includes low ffa vegetable oil ( soya, sunflower, etc.), palm stearin, high grade fatty acid & tallow oil. The glycerine phase will be discharged from bottom of the separation tank and then we will make two more products from them

Shri parth petrochem advantage:

- The plant is capable of manufacturing bio-diesel conforming to eu (en 14214) and bis 15607:2005 standards.

- Smooth and easy process.

- Distillation process.

- Glycerol process.

- 100 % customized plant available in batch type.

- Better Mileage

- Betters industry benchmarks in ash & moisture content, total contaminations and carbon residue indicators.

- Extremely low sulphur content; which helps checking air pollution.

- By product will be utilized in maximum way.

| Sr. no. | Characteristics | Is 1567 2005: |

| 1 | Density, kg / m 3 2005 | 0.84.5 -0.90 |

| 2 | Sester content, % | Min. 96.5 |

| 3 | Flash point (closed cup), °c | 120 |

| 4 | Water and sediment, mg / kg, | Max. 500 |

| 5 | Kinematic viscosity at 40°c, mm2 /s | 3.5 |

| 6 | Oxidation stability at 110°c, hours min. | 6 |

| 7 | Ramsbottom carbon residue, % mass, | Max. 0.05 |

| 8 | Sulphated ash% mass, | Max. 0.02 |

| 9 | Sulfur, mg / kg max | 50 |

| 10 | Copper strip corrosion 3 hrs. 50°c | Class 1 |

| 11 | Cetane number, min. | 51 |

| 12 | Acid number, mg koh/g, max. | 0.5 |

| 13 | Methanol or ethanol, % m/m, | Max 0.2 |

| 14 | Group i metal (na+k), mg/kg, | Max 5 |

| 15 | Group ii metal (ca+mg), mg/kg, | Max 5 |

| 16 | Phosphorus content, mg/kg, | Max 10 |

We provide services to our supplied customer:

- Training of operation

- Staff training

- Purchase of raw material tie up with suppliers

- Sales related tie up with buyers

- Production and operation of plant

- Tendering guidelines iocl / hpcl / bpcl

- License liaison works

Previous

Next