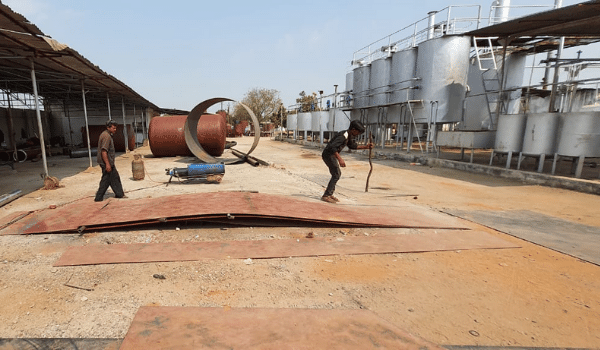

Essential Oils/ Perfumes Aroma Manufacturing Unit

History of Essential oils

Essential oils are used for many years; these come from ancient India, Persia & Egypt. Every country has many different uses that range from health treatments to spiritual practices. Incense, perfumes, clothing & fabric fresheners and medicines are included in the herbal preparations. In some countries, it is believed that aromatic oils are believed to create a union with the gods.

The plant distillation technique was first developed by the Arabs to extract essential oils. This replaced the fatty oils that were used as a solvent for extraction. In the middle ages, this technique spread to Europe & pharmacies that were specialized in distilled products.

What are Essential oils?

Essential oils are obtained from the different parts of the plants i.e. seeds, leaves, fruits, flowers, woods & resins. ‘Essential’ name is given because they capture the essence of the plant. These oils are given the name of the plant from which they are derived.

These oils contain the aroma of the plant from which they are derived. The plant is guarded against the attack of the parasites & animals; it allows them to adapt according to the environment. Pure essential oil is more powerful than the tree as its healing concentration is collected in the oil.

Composition of Essential oils:

Essential oils are the mixture of constituents; every oil has hundreds of constituents. These have wellness-enhancing & therapeutic properties. Most of the oils have the same constituents as their health-supporting & cleansing properties; almost every oil has anti-septic, anti-viral, anti-bacterial & antifungal properties.

Essential oils are colorless to any color of the rainbow, some colors point to the therapeutic qualities. Many times the colors are the result of the extraction method.

Extracting Essential Oils

A single drop of oil has many powerful health benefits. Micro drops of the oils can be stored with the gland of the plant. These drops can be diffused when these evaporate they fill the air with a pleasant aroma.

In the tropical region, plants with strong scent are found; these plants are used to produce biogenic volatile organic compounds. It takes more amounts to make a small amount of oil.

The essential is extracted by two methods: Steam Distillation, Solvent Extraction & Solvent Extraction Method.

| From where we can Extract essential oil | |

| FRUITS | LEAVES |

| STREAM | PLANT |

| PETALS | BARK |

RAW MATERIALS

- PINE OIL

- LEMON PEELS

- LAVENDER

- ROSE PEELS

- LAVENDER OIL

- ORANGE PEELS

- GERANIUM LEAVES

- GRAPEFRUIT OIL

- LEMON GRASS OIL

- CLOVE FLOWER / OIL

- EUCALYPTUS / NILAGIRI

- VETIVER

- GINGER

- NEEM OIL

- CHAMOMIL

- BASIL / TULS

- JASMINE OIL

- AJWAIN OIL

- TEA TREE OIL

- PEPPERMINT

- CAMPHOR OIL

- SANDALWOOD OIL

FINISHED GOOD

- ESSENTIAL OIL CONCENTRATED

- HYDROSOL WATER

INDUSTRIES IN WHICH YOU CAN SUPPLY

- PERFUME INDUSTRY

- PHARMA INDUSTRY

- FLAVOURED WATER INDUSTRY

- CAR FRESHENERS INDUSTRY

- JUICE MAKING INDUSTRY

- AROMA INDUSTRY

- COSMETIC INDUSTRY

- AGARBATTI / JOSS STICK INDUSTRY

- CANDLE MAKING INDUSTRY

WHAT IS STEAM DISTILLATION?

Steam Distillation is used for distilling volatile components from various raw materials, like spices, seeds, leaves, roots etc. These oils are generally recovered by directly applying steam to raw materials followed by condensation of the distillate. The temperature of the steam needs to be carefully controlled – just enough to force the plant material to let go of the essential oil, yet not too hot as to burn the plant material or the essential oil. Different components of these essential oils contribute to the characteristic fragrance and aroma. These oils can be customised to meet the exact requirement of the user.

UNIT MODELS

500 KG PLANT UNIT

-

Steam Distillation & Hydro Distillation Method

-

SPACE REQUIRED 500 SQ FT TO 1000 SQ FT

-

STAFF REQUIRED 1 TO 2 PERSON

-

ELECTRICITY REQUIRED 20 KWA TO 30 KWA

-

BATCH TIMING :- 10 TO 12 HOURS

-

LICENCE REQUIRED:- GST & FOOD AND DRUG DEPARTMENT

750 KG PLANT UNIT

-

Steam Distillation & Hydro Distillation Method

-

SPACE REQUIRED 500 SQ FT TO 1000 SQ FT

-

STAFF REQUIRED 1 TO 2 PERSON

-

ELECTRICITY REQUIRED 20 KWA TO 30 KWA

-

BATCH TIMING :- 10 TO 12 HOURS

-

LICENCE REQUIRED:- GST & FOOD AND DRUG DEPARTMENT

1000KG PLANT UNIT

-

Steam Distillation & Hydro Distillation Method

-

SPACE REQUIRED 1000 SQ FT TO 1500 SQ FT

-

STAFF REQUIRED 1 TO 2 PERSON

-

ELECTRICITY REQUIRED 30 KWA TO 50 KWA

-

BATCH TIMING :- 10 TO 12 HOURS

-

LICENCE REQUIRED:- GST & FOOD AND DRUG DEPARTMENT

2000KG PLANT UNIT

-

Steam Distillation, Hydro Distillation Method & Solvent Extraction Method

-

SPACE REQUIRED 1000 SQ FT TO 1500 SQ FT

-

STAFF REQUIRED 2 TO 3 PERSON

-

ELECTRICITY REQUIRED 50 KWA TO 75 KWA

-

BATCH TIMING :- 10 TO 12 HOURS

-

LICENCE REQUIRED:- GST & FOOD AND DRUG DEPARTMENT

OUR SERVICES

- RAW MATERIAL PROCUREMENT GUIDELINES

- SALES GUIDELINES

- PRODUCTION BATCH TRAINING

- GOVERNMENT LICENSE GUIDELINES